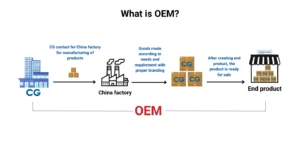

In international trade, the term OEM often comes up when buyers and suppliers discuss product customization and mass production. But what is an OEM manufacturer, and why is it important for industries such as home storage and travel products? This guide explains the meaning of OEM, how it works, and what buyers should look for when choosing the right partner.

What Does OEM Mean?

OEM stands for Original Equipment Manufacturer. In simple terms, an OEM manufacturer produces products according to another company’s design, specification, or branding.

Buyer’s role: Provides the concept, design, or brand guidelines.

OEM manufacturer’s role: Handles production, quality control, and delivery.

Final result: Products are sold under the buyer’s brand, not the factory’s name.

OEM vs ODM: What’s the Difference?

OEM (Original Equipment Manufacturer): Buyer provides design/specs → factory manufactures.

ODM (Original Design Manufacturer): Factory provides existing designs → buyer rebrands or slightly customizes.

👉 Example:

OEM → A European retailer gives detailed requirements for a new laundry bag, including fabric, size, and color. The manufacturer produces exactly to spec.

ODM → The same retailer selects a ready-made design from the manufacturer’s catalog and adds their own logo.

Key Characteristics of an OEM Manufacturer

Customization Capability

Materials (cotton, polyester, recycled fabric)

Colors and patterns (including fabric dyeing and printing)

Sizes, compartments, packaging

Technical Expertise

Ability to follow buyer’s technical drawings

Knowledge of industry standards (OEKO-TEX, REACH, BSCI audits)

Confidentiality

OEM factories usually produce under strict agreements to protect the buyer’s brand identity.

Why Work with an OEM Manufacturer?

1. Control Over Product Design

Buyers retain control over every detail, ensuring the final product matches market positioning.

2. Brand Building

OEM production allows companies to sell unique products under their own brand, strengthening market identity.

3. Quality and Compliance

Professional OEM factories have established QC systems and certifications required by global retailers.

4. Cost Efficiency

Instead of investing in factories, brands outsource to experienced OEM suppliers with existing infrastructure.

Applications in the Home Storage and Travel Industry

Fabric Storage Boxes

OEM manufacturers can produce customized storage boxes with specific colors, sizes, and reinforced structures according to retailer requirements.

Laundry Bags

Supermarkets and importers often provide detailed specifications (dimensions, fabric weight, packaging). OEM factories handle the entire production.

Travel Organizers

Amazon sellers and brand owners rely on OEM partners to create unique packing cubes, toiletry bags, or shoe organizers with custom branding.

What to Look for in an OEM Manufacturer

Experience & Scale

Years of production experience

Factory size and capacity (e.g., 10,000㎡ plant, monthly 60 HQ production)

Customization Portfolio

Proven track record of handling custom samples and bulk orders

Certifications & Compliance

BSCI, SEDEX, SGS test reports, eco-certifications

Communication & Service

Responsive team that understands buyer’s market requirements

Challenges in OEM Manufacturing

MOQ (Minimum Order Quantity): Some factories require high order volumes.

Lead Times: Customization often takes longer than ODM.

Design Accuracy: Requires clear specifications and close collaboration between buyer and factory.

Factory Insight: In our OEM projects for U.S. clients, we often create multiple pre-production samples to ensure final approval before mass production.

Future of OEM Manufacturing

Sustainability: Demand for recycled fabrics and eco-friendly production is rising.

Digitalization: Faster sampling using 3D design tools.

Flexible Production: Smaller MOQs for emerging brands.

These trends make OEM partnerships more accessible and aligned with global market needs.

Conclusion

So, what is an OEM manufacturer? It is a partner that turns your designs and concepts into finished products, helping you build a brand without owning a factory.

In the home storage and travel industry, OEM manufacturers play a vital role by producing custom storage boxes, laundry bags, and travel organizers that meet international standards.

👉 Looking for a reliable OEM manufacturer in home storage products? Contact us today to discuss your customization needs.