China remains the world’s largest exporter, supplying everything from textiles to electronics. For global buyers—especially those in home storage, travel accessories, or lifestyle goods—China offers competitive pricing, scalable production, and strong customization. But navigating the process can feel daunting if you are new.

This guide explains how to buy from Chinese manufacturers step by step: where to find suppliers, how to structure the order process, quality control measures, payment options, and common pitfalls to avoid.

Why Buyers Turn to Chinese Manufacturers

China’s manufacturing ecosystem is vast and mature, offering clear advantages:

Scale and efficiency – Factories operate with established supply chains, from raw materials to logistics.

Competitive cost structure – Lower unit cost due to economies of scale.

OEM & ODM capabilities – Flexible for both custom designs and ready-made solutions.

Export readiness – Many suppliers are already familiar with compliance requirements in the U.S., EU, and Japan.

Where to Find Chinese Manufacturers

1. Trade Shows

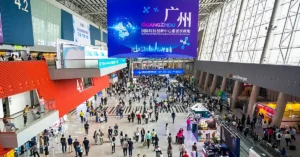

Canton Fair (Guangzhou) and Hong Kong Gifts & Premium Fair are major events.

Advantages: Touch and feel products, compare suppliers on the spot, establish personal trust.

Consideration: Requires budget for travel and accommodation.

2. B2B Platforms

Alibaba, Made-in-China, and Global Sources allow quick comparisons.

Advantages: Easy access to thousands of suppliers, fast quotations.

Consideration: Requires careful vetting; not every listed company is a direct factory.

3. Independent Factory Websites

Many mid-to-large factories invest in English websites to present their catalog and certifications.

Example: A textile manufacturer may highlight its BSCI audit and monthly production capacity.

4. Referrals and Networks

Recommendations from existing buyers, trade associations, or sourcing agents often lead to more reliable suppliers.

Step-by-Step Buying Process

Step 1: Define Your Requirements

Clarity reduces miscommunication. Specify:

Product dimensions, materials, and weight (e.g., 90 GSM polyester laundry bag).

Packaging details (polybag, carton size).

Compliance needs (OEKO-TEX, REACH, California Prop 65).

Step 2: Initial Inquiry & Quotation

Send RFQs (Request for Quotation) with exact details.

Compare offers not only on unit price but also MOQ, lead time, and payment terms.

Step 3: Sampling

Request pre-production samples.

Check stitching, color accuracy, fabric strength.

Adjust specifications before confirming the order.

Step 4: Order Confirmation

Sign a Proforma Invoice (PI).

Confirm key terms: delivery timeline, Incoterms (FOB, CIF, DDP), payment schedule.

Step 5: Production & Quality Control

Monitor progress through updates.

Arrange in-line QC checks for large orders.

Final inspection ensures goods match the approved sample.

Step 6: Shipping & Logistics

Sea freight is common for bulk orders.

Air freight suits small urgent shipments.

For Europe, China–Europe rail freight can be an alternative.

Quality Assurance and Compliance

Testing: Tear strength, colorfastness, wash durability—important for textile and storage products.

Third-party inspections: Services like SGS or Intertek can verify goods before shipment.

Certifications: Many retailers require BSCI, SEDEX, OEKO-TEX, or GRS (Global Recycled Standard).

Example: A European retailer sourcing cotton storage boxes often requests both colorfastness tests and social compliance audits before confirming bulk orders.

Payment Methods and Terms

T/T (Telegraphic Transfer) – Most common: 30% deposit, 70% before shipment.

L/C (Letter of Credit) – Used for larger orders to reduce risk.

Small payments – Samples or small trial orders may be paid via PayPal.

Tip: Always clarify banking details directly with the factory to avoid fraud.

Common Risks and How to Avoid Them

Unverified suppliers – Always confirm factory audits or business licenses.

Hidden costs – Clarify packaging, labeling, and freight responsibilities.

MOQ surprises – Some factories may set high minimums; clarify early.

Quality inconsistency – Solve with golden samples and third-party inspection.

Intellectual property risks – Use contracts with clear IP protection clauses.

Industry Insights: What Buyers Are Demanding Now

Smaller MOQs – More factories are open to 300–500 pcs per item, supporting smaller brands.

Sustainable materials – Recycled polyester, organic cotton, and eco-dyes are increasingly requested.

Faster lead times – Buyers want quicker sampling (2 weeks) and production (30–45 days).

Digital communication – Factories now use video calls, online sample approvals, and digital catalogs.

Conclusion

Learning how to buy from Chinese manufacturers is about more than finding the lowest price. It requires a structured approach: define your requirements, verify suppliers, sample carefully, and ensure compliance.

For industries like textiles, home storage, and travel accessories, China continues to offer unmatched supply chain efficiency. With proper due diligence, buyers can build lasting partnerships that balance cost, quality, and reliability.

👉 Interested in sourcing custom storage or travel products? Contact us today to discuss your requirements and request samples.