Fabric printing has evolved from traditional techniques to advanced digital methods, enabling industries to create unique, durable, and eco-friendly designs. If you are in the textile or home storage sector, understanding how to print on fabric is crucial for choosing the right process for your products. This article explores the main printing methods, their industry applications, and how fabric printing adds value to storage and travel products.

Why Fabric Printing Matters in the Industry

Printed fabrics are not just about aesthetics—they impact brand identity, functionality, and market competitiveness. For example, custom-printed fabric storage boxes or travel organizers can:

Differentiate products in competitive retail markets.

Enhance brand recognition with logos and patterns.

Provide seasonal or trend-based designs (florals, geometric prints).

Add perceived value, making products more appealing to end consumers.

Main Fabric Printing Techniques

1. Screen Printing

Process: Uses a stencil (mesh screen) to apply ink layer by layer.

Advantages: Bold colors, excellent for logos and simple designs.

Limitations: Labor-intensive, less cost-effective for small runs.

Applications: Widely used for promotional tote bags, fabric storage bins, and laundry bags.

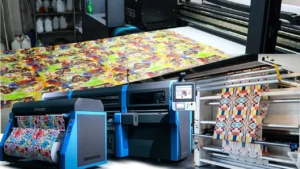

2. Digital Direct-to-Fabric Printing (DTG)

Process: Inkjet printers spray water-based inks directly onto fabric.

Advantages: High-resolution images, suitable for complex designs and small batches.

Limitations: Works best on cotton and natural fibers; higher unit cost.

Applications: Fashion apparel, customized travel pouches, small-batch storage products.

3. Dye Sublimation Printing

Process: Heat transfers dye into polyester fibers, creating vivid, permanent prints.

Advantages: Durable, vibrant, fade-resistant.

Limitations: Works only on polyester or polyester-coated fabrics.

Applications: Sportswear, banners, and polyester-based storage bags.

4. Heat Transfer Printing

Process: Pre-printed design is transferred onto fabric with heat and pressure.

Advantages: Flexible for short runs and seasonal designs.

Limitations: Less durable than sublimation; prints may crack over time.

Applications: Decorative storage covers, travel organizers, and custom gift bags.

How Printing Adds Value to Storage Products

1. Fabric Storage Boxes

Custom prints can turn basic storage bins into fashionable home décor items. For example, geometric or floral patterns make storage boxes blend seamlessly with modern interiors.

2. Laundry Bags

Printed designs add personality and brand recognition, while functional prints (such as care instructions or icons) increase usability.

3. Travel Organizers

Personalized prints, logos, or trendy patterns enhance retail appeal, especially for Amazon sellers and boutique brands.

Industry Considerations When Choosing a Printing Method

Fabric Type

Cotton → best for screen printing and digital direct print.

Polyester → ideal for sublimation.

Blends → may require specialized inks.

Order Volume

Large runs → screen printing is cost-effective.

Small runs or samples → digital printing offers flexibility.

Durability Requirements

Home storage products require prints that resist fading, rubbing, and washing.

Cost and Lead Time

Digital and heat transfer are faster for small batches.

Screen printing is slower but cheaper per unit for bulk orders.

Future Trends in Fabric Printing

Eco-friendly dyes – water-based and low-impact inks are becoming standard.

On-demand customization – digital printing enables brands to test designs quickly.

Smart printing – QR codes and functional prints are emerging in packaging and storage industries.

These trends align with customer demand for sustainability, personalization, and durability.

Conclusion

Understanding how to print on fabric is essential for industries that rely on textiles, from fashion to home storage. Each printing method offers unique benefits, and the right choice depends on fabric type, order size, and end-use.

For storage products, printing isn’t just decoration—it’s a way to increase market value, build brand recognition, and align with consumer trends.

👉 Looking for custom-printed storage products? Contact us today to discuss your design and order requirements.